The Quality Chart

CPIE's principal aim is to offer to its customers a reliable source of supply.

Thus, the company endeavours to obtain, from the producers, the necessary information to ensure a secure commercial deal.

Thus, the company endeavours to obtain, from the producers, the necessary information to ensure a secure commercial deal.

The whole process from the order to the delivery is made in accordance with a CPIE quality standard procedure accepted and signed by the CPIE staff as well as all the suppliers. Suppliers include mine owners as well as road transportation, port authority, freight forwarder and the quality control company.

For each transaction, a first random test is conducted at the mine by one of the international quality control company such as SGS, Alex Steward, Intertek, etc. The tests are made from the chosen lot that is pre-booked for the delivery. The tests cover the following criteria’s:

- Physical composition product (Nominal size, moisturizing, etc.)

- Chemical product composition

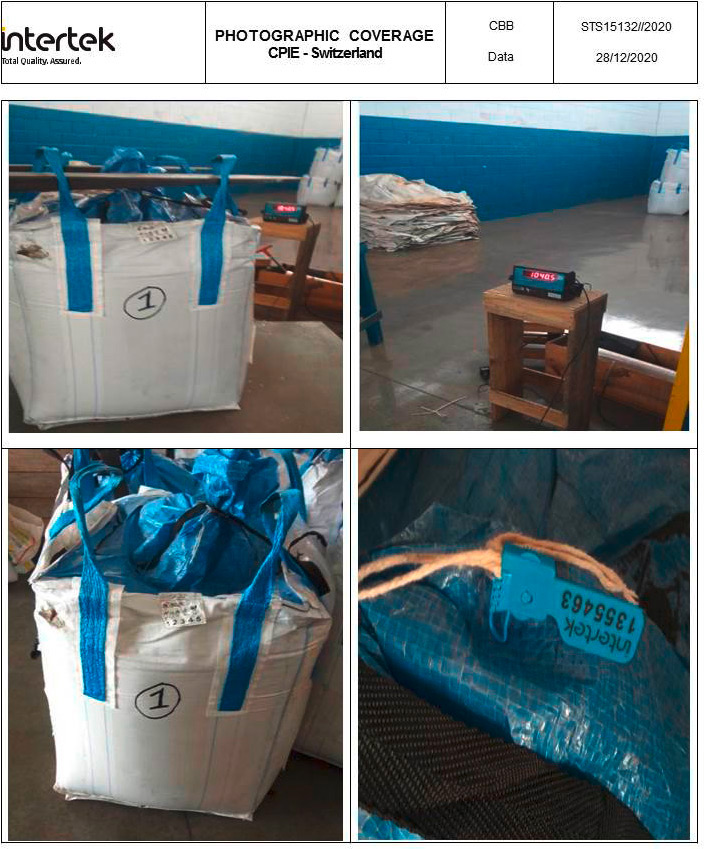

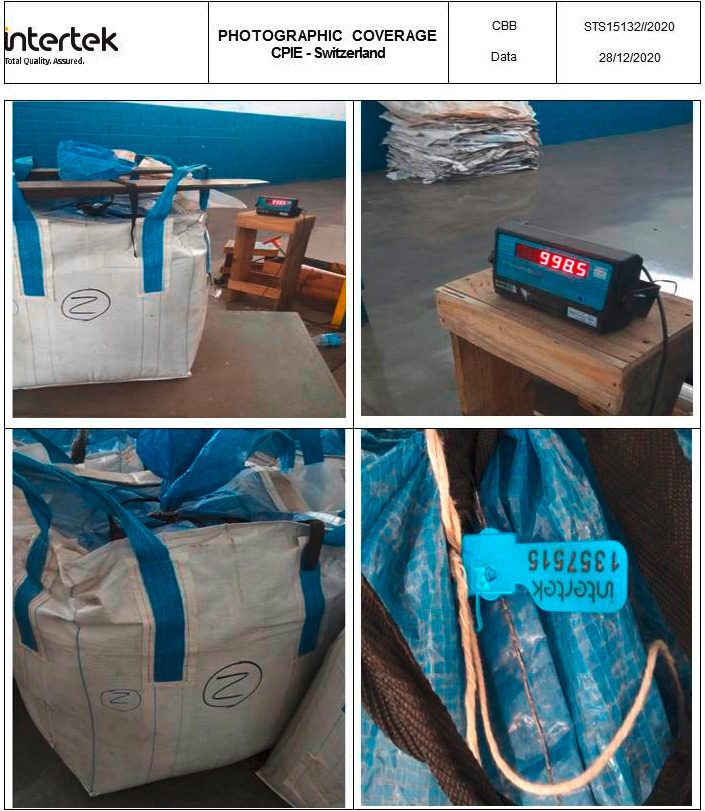

- Weight at Mine site and at loading port

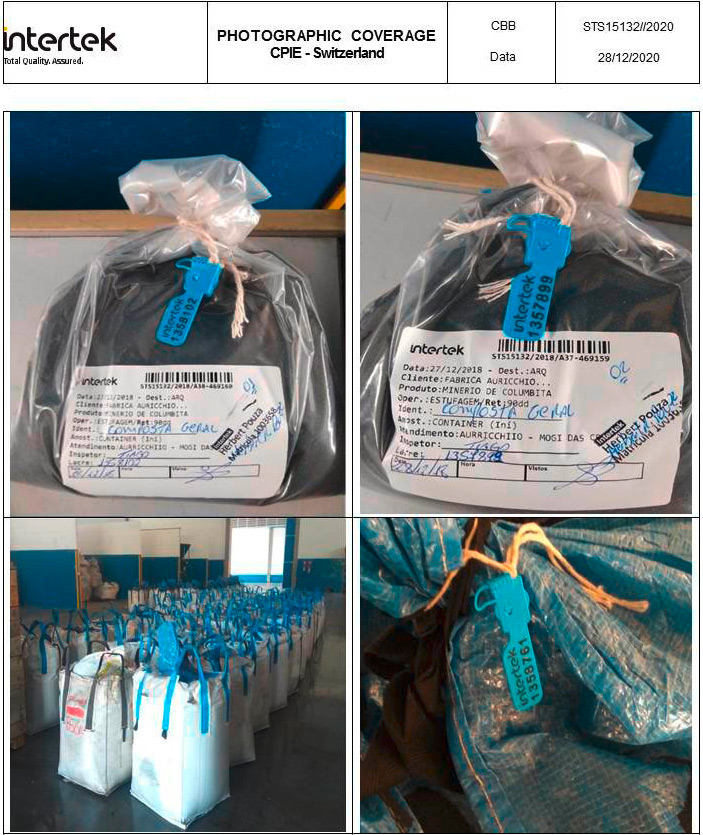

Once the test is realized, the first test certificate is submitted to the final customer who must approve the quality. After approval, minerals are loaded in sealed big bags or bulks ready for road transportation from the mine to the closest port.

At port arrival, the same controller will ensure that the big bags are still sealed and that the quantity concords with the ordered quantity. Before up loading on board, a final test is conducted as to check again all criteria above mentioned and the bag or bulks are sealed again ready for shipping.

A new certificate is delivered by the controller and submitted to the final customer with all documents requested in the purchase agreement or the letter of credit. Usually, CPIE work with FOB incoterm. Thus, from on board loading the responsibility of the good is under final customer responsibility. Nevertheless, a final test is conducted under final customer responsibility at arrival port as to control the adequacy between off loaded shipment as delivered shipment.

At port arrival, the same controller will ensure that the big bags are still sealed and that the quantity concords with the ordered quantity. Before up loading on board, a final test is conducted as to check again all criteria above mentioned and the bag or bulks are sealed again ready for shipping.

A new certificate is delivered by the controller and submitted to the final customer with all documents requested in the purchase agreement or the letter of credit. Usually, CPIE work with FOB incoterm. Thus, from on board loading the responsibility of the good is under final customer responsibility. Nevertheless, a final test is conducted under final customer responsibility at arrival port as to control the adequacy between off loaded shipment as delivered shipment.